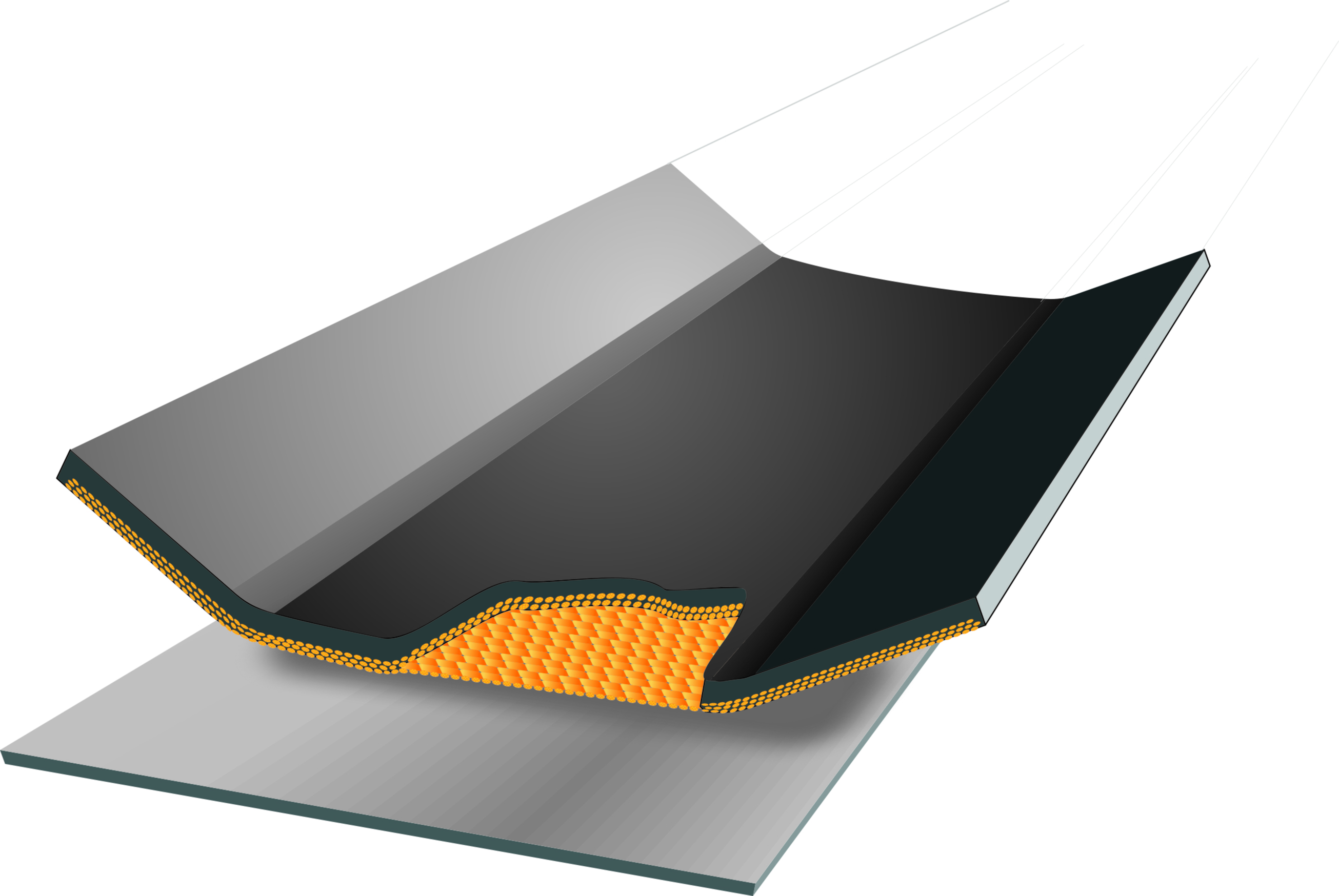

DBP OilTECH

Oil-resistant G grade

DBP OilTECH covers provide good tear, cut and abrasion resistance and also are resistant to swelling when caused by absorption of oils and grease.

The oil resistant cover is available in two grades, DBP OilTECH and DBP OilTECH +. They are used when the material transported contains oils such as fuel oil in coal or fertilizers, lubrication oils in metal recycling, foundries, steel processes, waste industries or in the case of special processes such as glass or chemical.

The presence of oil in the transported material can have detrimental effects on standard rubber covers:

- it will degrade the physical properties such as abrasion resistance, tensile strength and tear strength;

- the belt covers will absorb the oil causing them to swell and loose adhesion with the carcass.

The extent of degradation is dependant on the type of oil and the temperature. There is an exponential increase in rate of degradation and amount of swelling with respect to the increase in temperature. Therefore, it is important to consider the operating temperature and types of oily substances when choosing the most suitable DBP OilTECH cover. Oil resistance of a belt cover is evaluated by measuring the swelling of the rubber after immersion in oil. For purposes of comparison specifications of oils used for the evaluation are standardised.

The two standard oils:

- IRM902, a medium aggressiveness oil;

- IRM903, is an aggressive oil containing naphthenic, aromatic and aliphatic constituents.

Specifications

| Cover Type | Characteristic | Cover Properties | Swelling Test | ||||

|---|---|---|---|---|---|---|---|

| Tensile Strength (MPa) | Elongation at Break (%) | Abrasion (mm3) | % Swell after immersion in IRM902 for 28h | % Swell after immersion in IRM903 for 72h | |||

| DBP OilTECH G | Medium oil resistance | 16 | 400 | 150 | 15 | ||

| DBP OilTECH G+ | Superior oil resistance | 16 | 400 | 140 | 5 | ||

| DBP OilTECH G1 | Medium oil resistance and fire resistant according to DIN ISO 340 | 16 | 450 | 170 | 15 | ||

More products...

DBP WearTECH

The conveyor belt benchmark for wear-resistance The combination of tensile strength, abrasion resistance and elasticity of the conveyor cover are…

Read more

DBP LavaTECH

Heat-resistant HR GRADE Our range of DBP LavaTECH is descriptive and includes the resistance to heat and heated material conveyed.…

Read more

DBP OilTECH

Oil-resistant G grade DBP OilTECH covers provide good tear, cut and abrasion resistance and also are resistant to swelling when…

Read more

DBP SlideTECH

DBP SlideTECH incorporates a special high density fabric weave preventing rubber striking through during vulcanization. There is no rubber on…

Read more