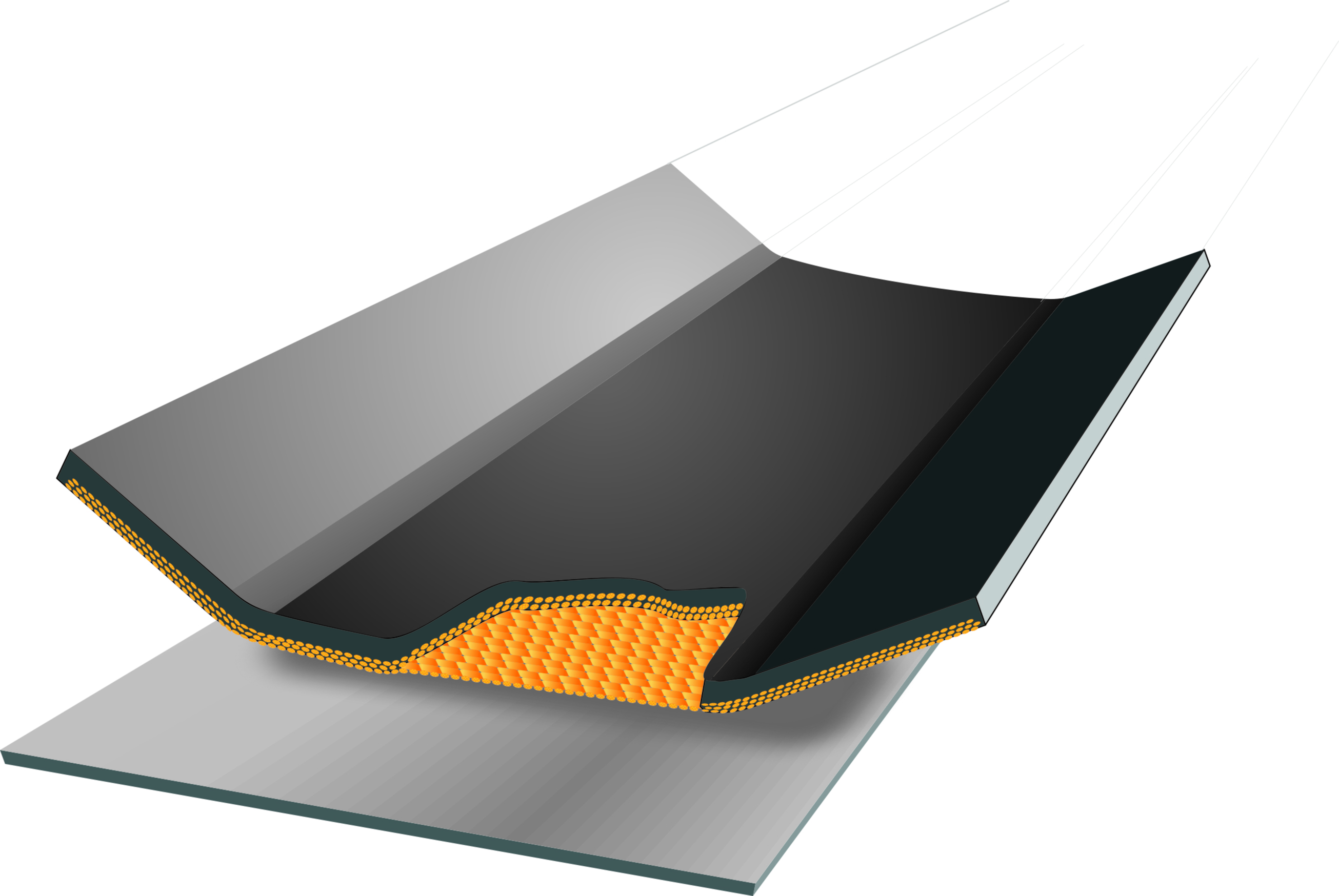

DBP FlameTECH

Fire retardent V grade

DBP FlameTECH conveyor belting has rubber covers that provide good tear, cut, impact and abrasion resistance and is also fire retardant.

The belt is available in a complete range of multiply strengths and also with steel cord reinforcement. Tests carried out on DBP FlameTECH conveyor belting for determining fire retarding properties.

- Flame test – ISO 340:2013 test method

- Electrical conductivity of the belt surface – ISO 284:2012 test method

- Fire propagation test – EN 12881−1 test method

| Safety level | Standard norm/tests | Belting name | Risk |

| Level 1 | hardly inflammable according to ISO 340 DIN EN 12882 2A-2B | DBP FlameTECH EP or ST Level 1 | Prevention of the propagation of accidental fire from a minor fire source aboveground and the risk of explosion due to the accumulation of static electricity. |

| Level 1 | hardly inflammable according to ISO 340 DIN EN 12882 2A-2B | DBP FlameTECH EP or ST G1 – Level 1 | Idem safety level 1 and additionally oil-resistant. |

| Level 2 | DIN EN ISO 12882 according to customer specification | DBP FlameTECH EP or ST Level 2 | Prevention of the propagation of accidental fire from an extensive fire source aboveground and the risk of explosion due to the accumulation of static electricity. |

| Level 3 | DIN EN ISO 14973 according to customer specification | DBP FlameTECH EP or ST Level 3 | Prevention of the propagation of accidental fire from an minor or extensive fire source underground, the risk of explosion due to the accumulation of static electricity and the risk of belt blockage. |

Specifications

| Cover | Abrasion < mm3 | Elongation at break min. in % | Min. ambient temperature in °C |

Constant material temperature in °C |

Max. temporary material temperature in °C |

Polymer basis |

| K/S | 200 | 350 | -20 | 80 | 90 | SBR |

| VT or V | 175 | 350 | -20 | 80 | 90 | CR |

Fire retarding specifications

| Flame test – ISO 340: 2013 | Electrical Conductivity ISO 284 : 2013 | Fire propogation – EN 12881 – 1 Method C |

| Total of 6 samples extinguish within 45 seconds Maximum duration of flame or glow for any single sample is 15 seconds |

< 300 Megaohm | a) the length of the test piece that remains undamaged across the whole width of the test piece shall be not less than 600 mm; or b) the maximum average temperature rise shall not exceed 140 °C, the length of belting consumed by mass shall not exceed 1250 mm and the length of the test piece that remains undamaged shall be not less than 50 mm across the whole width of the conveyor belt. |

More products...

DBP WearTECH

The conveyor belt benchmark for wear-resistance The combination of tensile strength, abrasion resistance and elasticity of the conveyor cover are…

Read more

DBP LavaTECH

Heat-resistant HR GRADE Our range of DBP LavaTECH is descriptive and includes the resistance to heat and heated material conveyed.…

Read more

DBP OilTECH

Oil-resistant G grade DBP OilTECH covers provide good tear, cut and abrasion resistance and also are resistant to swelling when…

Read more

DBP SlideTECH

DBP SlideTECH incorporates a special high density fabric weave preventing rubber striking through during vulcanization. There is no rubber on…

Read more